WHAT THE FACT? Cook-Chill with Joni

Hopefully by now you have an understanding of the advantages of volume cooking with Joni (if not, read this!). But one of the areas where the Joni range truly performs is when used for the cook-chill process, and today we dive a little deeper and take a look at how this works.

Whilst all models of the Joni commercial kettle range are applicable for a volume production kitchen, the OptiMix is the kettle of choice for the cook-chill process as it has the option of connecting to an external chilling system or to the main water supply to rapidly chill its contents.

How?

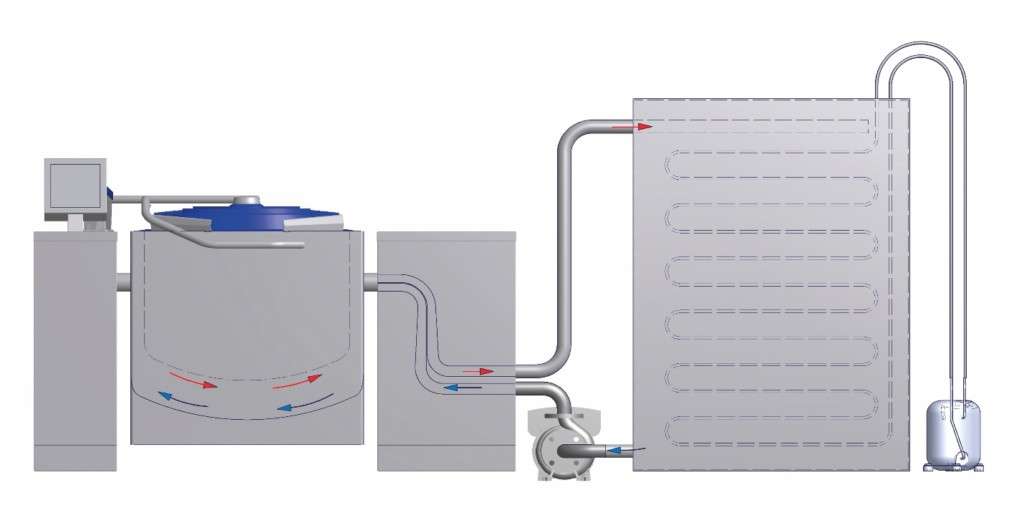

If using an external chilling system, after the cooking process is complete hot water in the steam jacket is pumped out of the unit and circulated through an ice bank, chilling the water which is then fed back through the steam jacket where it chills the contents of the kettle. When the chilling ends, the correct water level in the steam generator is automatically restored. The dimensions of the chilling system and the ice bank/chilled water reservoir will depend on the number and size of kettles and the expected number of chilling’s per day. These dimensions must therefore be determined by us at Comcater or a chilling systems contractor, who can also assess whether the existing chilling equipment can be reused, whether a supply of ice/ chilled water can be built up overnight when electricity is cheap, etc.

This is a highly efficient way of chilling the product as water consumption is low and the temperature of the water is usually 0.5⁰C, preventing edge chilling as the water is above freezing point. The stirrer will rotate slowly and gently but rapidly treat the food making it the quickest and easiest way to chill food while maintaining its desired consistency.

The kettle also allows for chilling via the mains supply of water, as water is fed through the steam jacket, where it chills the contents of the kettle. It then drains via the floor grate. This is a simple way of chilling, but the water consumption is relatively high and the chilling effect depends on the temperature of the water.

Joni’s OptiMix range is supplied as standard with AutoTemp 35 control, which includes electric tilt with TiltBack, digital control and display of the inner kettle temperature, stirrer control, an electronic water flow meter, a clock with an alarm function and WaterLevelAutomatic. These standard features ensure operators are across every step of the cook-chill process, with food safety the highest priority.

As an option the kettle is available with the more advanced AutoTemp 55 control, in which the chilling step is set directly on the control panel and the function automatically optimises the quantity of water in relation to the chosen chilling step and food temperature. When the chilling process finishes, the correct water level in the steam generator will automatically be restored.

Volume cooking and chilling has never been easier with Joni. To discuss this further, fill in the form and we will be in touch!